C-007 |Mgt of material carrierslocations andproduction process in a textile mill

Factory Storage

| System Feature |

1. More than 1000 material carriers are placed in the factory. It is tedious to look for a designated material carrier.

Inefficiency and time waste slow down the production process, hence, overall operation cost increases.

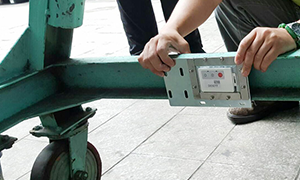

2. TAG is installed in a material carrier. The signals are constantly transmit to ensure that TAG functions normally.

3. When a material carrier moves, the location system keeps track of delivery process of carriers to next process

line and detects unusual delay of the carriers in production line.

4. The trace of carriers in a large scale building is effectively improved.

| Scenarios |

|

Factory list |

Factory list |

Factory list |

|

Factory list |

Product Application |

Product Application |

|

Product Application |

Product Application |

Product Application |

|

Product Application |

Product Application |

Product Application |

|

Product Application |

Product Application |

Product Application |

|

Product Application |

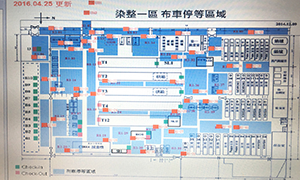

Scheme layout |

Scheme layout |

| Relative Devices |

|

Card Type TAG Model:PTAG-8454 |

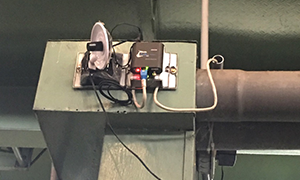

ZigBee Industrial Type Node Model:ZB2530-LAN-02 |

ZigBee Commercial Type RP Model:ZB2530-01RP |